charpy impact test for nylon|charpy impact testing procedure : specialty store Charpy testing is a method for determining the relative impact strength of metals. It is also known as the Charpy V notch test. This testing method was developed in the 1940s by S.B. Russell and G. Charpy.

webWatch your team & chat with fans from around the world on ELEVEN, the world's biggest live football streaming platform. Free & legal streams, 24/7 | ELEVEN.

{plog:ftitle_list}

Resultado da 855 likes, 33 comments - catarinaraminhos on February 29, 2024: "Eita semana chata! Até fui ao brinco mais alegre para ver se a coisa arrebita .

Test methods used to measure Notched Izod Impact (or notch sensitivity) and Charpy Impact in plastics are: ASTM D256-10(2018): Plastics — Determination of Izod pendulum impact resistance; ISO 180:2019: Plastics — Determination of .

The most common configuration for pendulum impact test are Izod and Charpy ones. The scope of these impact test is to measure the answer of a standard test specimen to the pendulum .

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact .1.1 This document specifies a method for determining Charpy impact properties of plastics from force-deflection diagrams. Different types of rod-shaped test specimens and test .The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .

Charpy testing is a method for determining the relative impact strength of metals. It is also known as the Charpy V notch test. This testing method was developed in the 1940s by S.B. Russell and G. Charpy. Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . Polyamide 6 - . Charpy impact test results are measured in joules, the SI unit for energy. This is simply the amount of work performed by a 1-newton force pushing a sample by 1 m in the direction of the force. This value can be used to . Charpy Test - Determination of Impact Energy Using the Charpy Test Polyamide 6/6 - Nylon 6/6 - PA 6/6 High Impact A swinging pendulum then breaks the metal beam, and the total energy absorbed by the metal is .

charpy impact testing procedure

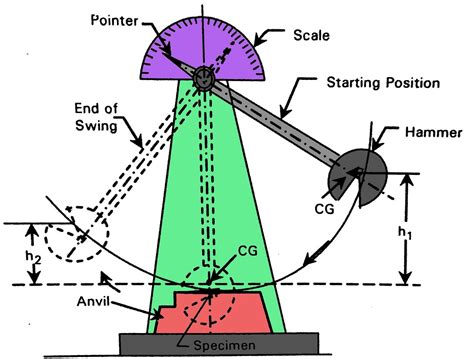

The objective of the Charpy impact test to ISO 148-1 is the determination of the impact energy and determination of the impact strength of a metal. The test indicates whether the metal is tough or brittle. In addition, the tough/brittle transition can be determined based on the temperature. Impact strength is a material characteristic value. 5.3 For this test method, the energy lost by the pendulum during the breakage of the specimen is the sum of the energies required to initiate fracture of the specimen; to propagate the fracture across the specimen; to throw the free ends of the broken specimen (toss energy); to bend the specimen; to produce vibration in the pendulum arm; to produce vibration or . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm.

charpy impact testing methods

Charpy Impact Test ISO 179. Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. The values recorded can be used for quality control or to simply .PROPERTIES Test methods Units VALUES Colour - - black Density ISO 1183-1 g/cm³ 1.29 . Charpy impact strength - Unnotched (13) + ISO 179-1/1eU kJ/m² 50 . this 30 % glass fibre reinforced and heat stabilised nylon grade offers increased strength, stiffness, creep resistance and dimensional stability whilst retaining an excellent wear .

This research employs the Taguchi method and analysis of variance (ANOVA) to investigate, analyze, and optimize the impact strength of tough polylactic acid (PLA) material produced through fused deposition modeling (FDM). This study explores the effect of key printing parameters—specifically, infill density, raster angle, layer height, and print speed—on Charpy .The impact strength of nylon was determined by the modified Charpy test with double-V notches described in DIN 53 753, because it cannot be reliably assessed by the notched . whether the Charpy impact test would yield better results. For various reasons, the notched impact test with a U-notch according to DIN53453 and ISO 179/2C is unsuitable .

Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3).specimen is equated to the "impact energy." The Charpy impact test uses a standard Charpy impact machine to evaluate this impact energy. The machine consists of a rigid specimen holder and a swinging pendulum hammer for striking the impact blow to a v-notched specimen as shown in Figs. 1 and 2.Both methods characterize the impact strength of a material in very similar ways so that the results largely correlate. The Izod test method, in which the specimen is positioned vertically, is normally used in ASTM standards.; The Charpy impact test, which uses a three-point bending arrangement, is the preferred method in ISO standards.; Both methods are used to measure .

precedence over those required by this test method. Table 1 of ClassiÞcation D4000 lists the ASTM materials standards that currently exist. If there is no material speciÞcation, then the requirements of this test method apply. 5.2 The pendulum impact test indicates the energy to break standard test specimens of speciÞed size under stipulated The impact fracture behavior of a high-density polyethylene (HDPE) material is investigated experimentally and theoretically. Single-edge notched bending (SENB) specimens are tested in experiments with three-point bending and in the Charpy impact tests. An energy model is proposed for evaluating the HDPE impact toughness, which provides a description of .1.1 This document specifies a method for determining Charpy impact properties of plastics from force-deflection diagrams. Different types of rod-shaped test specimens and test configurations, as well as test parameters depending on the type of material, the type of test specimen and the type of notch, are defined in ISO 179-1.

Charpy impact strength is significantly affected by the interfacial bond strength, by extension the interlaminar shear strength (ILSS), which is controlled by fiber surface treatments and manufacturing processes [12], [13], [19].The fracture initiation energy during Charpy impact testing increases with increasing ILSS, and displays a minimum when a critical value of ILSS .ISO 179-1:2010 specifies a method for determining the Charpy impact strength of plastics under defined conditions. A number of different types of specimen and test configurations are defined.CHARPY IMPACT TEST ISO 179 Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. The values recorded can be used for quality

Peel Tester exporter

Temperatura: Las propiedades de tenacidad de un material pueden variar con la temperatura. Algunos materiales pueden volverse más frágiles a temperaturas bajas. Procesamiento térmico: Los tratamientos térmicos, como el temple y el revenido, pueden alterar las propiedades de tenacidad del material. Conclusión. La prueba de impacto Charpy es una .

The document provides details on conducting a Charpy impact test to evaluate the mechanical properties of materials. It describes the theory behind impact testing, the key equipment used - including specimens, a Vernier caliper, Instron Ceast 9050 impact tester, and microscope. It also outlines the step-by-step procedure for setting up and performing an impact test, which .Resultado de los ensayos Charpy variando el ángulo de carga a) Nylon b) PVC . Rev. Mex. Fı́s. . Steel - Charpy V-notch pendulum impact test - Instrumented test method, ISO 14556:2000. 5. Standard Methods for Notched Bar Impact Testing of Metallic Materials, E 23, Annual Book of ASTM Standards, v.03.01, ASTM, Philadelphia, 1984. 57 6. Impact testing is a complex and controversial subject, and one that is in the midst of change. . including nylon 6 and 66. 23 Aug 2024. Prices of PE, PP, PVC Up; PS, PET Flat . standards for testing commodity resins. However, for engineering and specialty resins, there is indeed a move toward Charpy impact testing. "The automotive people .

The Charpy impact test was conducted at -70~ for SN490B steel and at -100~ for SHY685N steel to induce brittle over a large portion of the notch section. The impact test machine had a pendulum striker of 447 N with an arm length of 850 mm, which produced the initial potential energy of 490 J. Measuring devices were instrumented as shown in Fig. 2.

Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test. Material testing - Impact test: Charpy. The need to get reliable data from repeatable tests that can be used by designers for the material choice is the main reason why a number of standardized tests have developed over time to define materials. What is the impact test? One kind of test concerns impact tests.

Charpy impact test's ability to detect an intentionally introduced defect in a tested sample is studied, involving exploitation of force-displacement data recorded during the test on reduced-size samples. For a defect localized within the notch plane, the results show that reduced-size samples allow for detecting a localized defect. .

charpy impact test sample

21 de dez. de 2023 · Aged 14, and having grown accustomed to city life, Autumn discovers her childhood village is under threat from animal traffickers and decides she must return .

charpy impact test for nylon|charpy impact testing procedure